ISO Certification In Al Jubail

Get Free Consultation

Popularcert, your trusted partner for ISO certification in Al Jubail. Achieving ISO certification reflects your commitment to quality and global standards. Popularcert simplifies the certification process, ensuring efficiency and compliance. This unlocks valuable benefits for businesses in Al Jubail and beyond.

ISO certification in Al Jubail plays a vital role in supporting businesses aiming for operational excellence and global recognition. As a key industrial hub in Saudi Arabia, Al Jubail’s organizations benefit from ISO standards by improving quality, efficiency, and compliance with international requirements. Whether it’s ISO 9001 for quality management or specialized certifications, achieving ISO certification enhances customer trust and competitiveness. For reliable ISO certification services in Al Jubail, Popularcert is a trusted partner committed to guiding businesses toward success.

Why do we need ISO certification in Al-Jubail ?

ISO certification in Al-Jubail is essential because, it helps businesses improve their processes, ensure product quality, and build trust with customers. As a major industrial city, many companies in Al-Jubail need to meet international standards to stay competitive and expand globally. ISO certification also ensures compliance with local and global regulations, making operations smoother and more efficient. Whether for quality, safety, or environmental standards. Applying for ISO certification is a smart step toward long-term growth and success.

How to Get ISO Certification In Al Jubail?

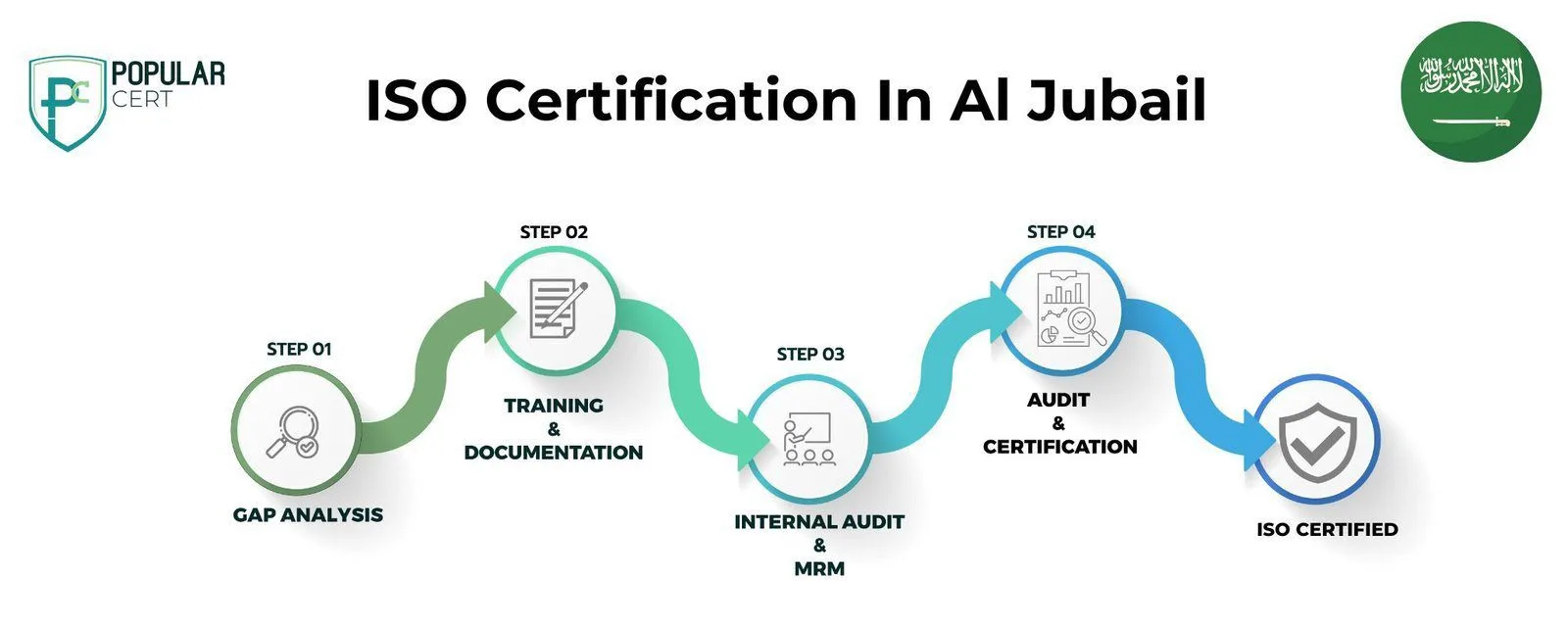

Process to Get ISO Certification In Al Jubail

Consultation and Gap Analysis

Organizations in Al Jubail begin by assessing their existing management systems against the relevant ISO standards. This gap analysis helps identify areas for improvement or adjustment.

Planning, Documentation, and Policy Development

Once the gaps are identified, the organization creates the necessary documentation, such as a comprehensive manual, procedures, and records that align with ISO certification requirements.

Training and Awareness

The documented system is then put into practice. Employees are trained on the new procedures and protocols to ensure the system's effectiveness.

Internal Audit and Management Review

Internal audits are conducted to identify non-conformities or areas for improvement, enabling the organization to address them proactively. Top management assesses the system’s overall performance to ensure it aligns with the organization’s strategic goals.

External Certification Audit and Certification

We work closely with accredited certification bodies to facilitate the external audit process for ISO certification. Once the audit is successfully completed, we assist in obtaining the ISO certification. Additionally, PopularCert provides ongoing support, including surveillance audits and expert guidance to ensure continuous compliance and improvements in the management system.

Benefits of ISO Certification in Al Jubail

-

Enhanced Credibility and Reputation : ISO certification boosts the credibility and reputation of organizations in Al Jubail. It signals to clients, partners, and stakeholders that the company adheres to international standards, which fosters trust and confidence.

-

Improved Operational Efficiency : Achieving ISO certification leads to streamlined processes and better resource management. By following structured guidelines and standardized procedures, companies can reduce waste, increase efficiency, and optimize performance.

-

Better Risk Management : ISO standards help organizations identify, assess, and mitigate risks more effectively. This proactive approach reduces the likelihood of problems and ensures better decision-making, particularly in areas related to safety and compliance.

- Increased Market Opportunities : ISO certification opens doors to new business opportunities, both locally and globally. In Al Jubail, where industries are highly competitive, ISO certification can differentiate a business from others and improve its chances of securing contracts.

-

Regulatory Compliance : ISO certification ensures that organizations meet all relevant legal, regulatory, and environmental requirements. It provides a framework for staying compliant with industry regulations, minimizing the risk of fines or legal issues.

-

Continuous Improvement : ISO certification encourages a culture of continuous improvement. By focusing on regular audits, performance reviews, and feedback, organizations can adapt to changes, enhance customer satisfaction, and stay competitive in the marketplace.

Types Of ISO Certification In Al Jubail

Get Free Consultation

Our Clients

Why Choose PopularCert For ISO Certification in Al Jubail?

PopularCert is a leading global consultancy with skilled experts helping businesses implement ISO standards. Our mission is to guide companies toward success by aligning their practices with global best practices. With a focus on simplicity, transparency, and quality, we ensure our clients understand every step of the process. We don’t just train teams; we enhance their implementation skills for lasting results.PopularCert has a proven track record of successful ISO certifications in Al Jubail. Our consultants guarantee high-quality services, and we offer competitive pricing to help businesses achieve certification and strengthen their market position effectively.

Cost of ISO Certification in Al Jubail

The cost of ISO Certification in Al Jubail depends on your business size and industry. PopularCert streamlines the process by offering tailored solutions that fit your specific requirements. Partnering with PopularCert ensures a hassle-free certification experience, helping you improve operational efficiency and stay competitive.

Apply for ISO Certification with PopularCert to boost your market presence, build customer trust, and drive sustainable business growth.

FAQ

What is ISO certification, and why is it important for businesses in Al Jubail?

ISO certification demonstrates that an organization meets international standards for quality, safety, and efficiency. It helps businesses in Al Jubail build credibility, improve operations, and access new market opportunities.

How long does it take to achieve ISO certification?

The timeline depends on the organization’s size, complexity, and readiness. On average, the process can take 3 weeks to Month, including preparation, implementation, and audits.

Which industries in Al Jubail benefit most from ISO certification?

Industries like manufacturing, petrochemicals, construction, logistics, and food processing in Al Jubail benefit significantly, as ISO standards enhance quality, safety, and compliance in these sectors.