GMP certification in UGANDA

Get Free Consultation

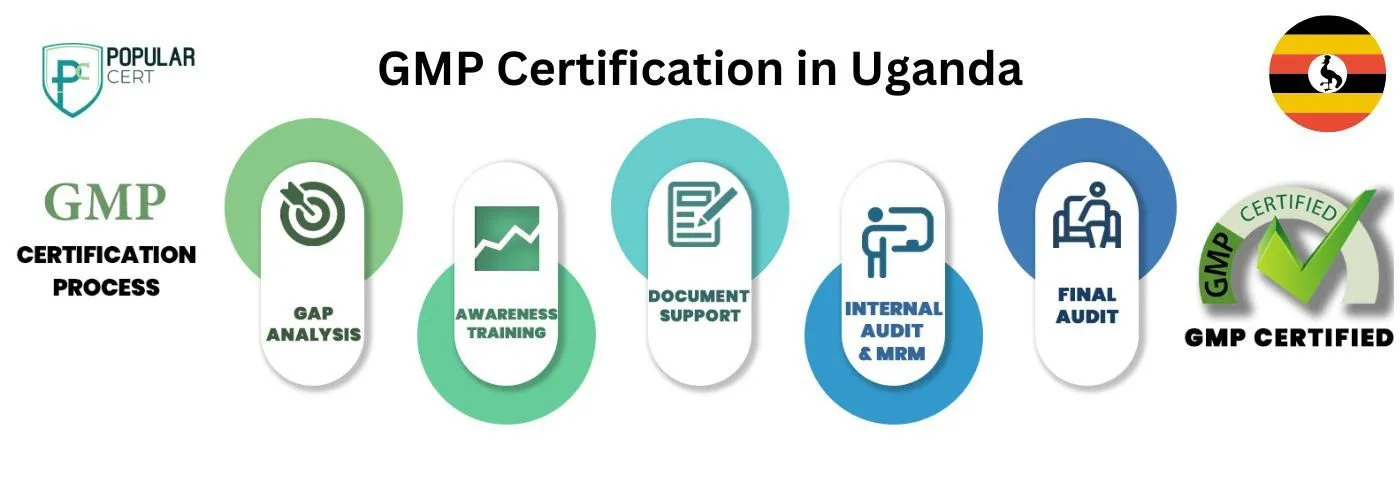

PopularCert provides expert assistance in Uganda, helping organizations navigate the complexities of GMP certification in Nigeria by offering gap analysis, technical documentation support, process assessment coordination, and audit preparation. With PopularCert, businesses can achieve GMP certification efficiently and enhance their reputation for quality and safety. The certification process involves facility inspection, process evaluation, documentation, and compliance assessment, ensuring that companies meet both local and international GMP standards.

In Uganda, two main regulatory groups enforce GMP. These include the National Drug Authority (NDA) for medicine and the Uganda National Bureau of Standards (UNBS) for food, drinks, cosmetics, and other goods for consumers.

Why GMP Certification is important for you and your business in Uganda.

GMP certification is essential for businesses in Uganda as it ensures compliance with international standards and guarantees the safety and quality of products. It helps organizations meet required guidelines, reduce risks, and improve process reliability. Additionally, GMP certification enhances brand reputation and creates opportunities in both local and international markets. Adopting GMP certification strengthens a company’s competitive edge by showcasing its commitment to high-quality, safe, and compliant manufacturing practices, building trust and reliability in global trade.

GMP covers every aspect of product creation, from raw materials to staff training, addressing risks that final product testing or intermediate stages might miss. Key areas include building conditions, sanitation, equipment maintenance, raw material sourcing, stringent production controls, and proper records and reporting.

How to Get GMP Certification in Uganda?

Process to Get GMP Certification In Uganda

Consultation and Gap Analysis

PopularCert’s experts begin by understanding your organization’s needs and current manufacturing practices. We then conduct a gap analysis to identify areas requiring improvement to achieve GMP certification in Uganda, ensuring your organization is well-prepared to meet both local and international quality and safety standards.

Planning, Documentation, and Policy Development

Based on the gap analysis, we develop a detailed implementation plan, allocate resources, and assist in creating essential policies and documentation required for GMP certification in Uganda. These policies and procedures are seamlessly integrated into your existing framework, ensuring compliance with GMP standards and effective implementation across your operations, from raw material sourcing to final product testing.

Training and Awareness

We provide comprehensive training for your staff, ensuring they understand the requirements of GMP certification and their role in effectively implementing and maintaining GMP standards. Our training programs are tailored to meet the specific needs of organizations in Uganda, empowering your team to successfully achieve and sustain GMP certification, ensuring compliance with safety, quality, and manufacturing practices throughout your operations.

Internal Audit and Management Review

After implementing the GMP standards, we conduct an internal audit to assess the effectiveness of your processes and identify any non-conformities. Following this, a management review is carried out to ensure that the system aligns with your organization's goals and compliance requirements in Uganda, ensuring that you are fully prepared for GMP certification and capable of maintaining ongoing compliance with safety and quality standards.

External Certification Audit and Certification

After successfully completing the external audit by the certification body, your organization will be awarded GMP certification. This certification highlights your commitment to maintaining high standards of manufacturing practices and continuous improvement. It demonstrates your dedication to quality, safety, and compliance, enhancing your credibility and building customer trust, especially for organizations in Uganda.

Benefits of GMP Certification in Uganda

- Better Product Quality : Having a GMP certificate means your product meets high-quality standards. It helps to cut down flaws and keeps product quality the same.

- Following Regulations : GMP certificate helps businesses to meet legal needs. It decreases risk of legal problems and makes sure products can be sold in many markets legally.

- More Trust from Customers : GMP certificate is a sign of quality that wins customer trust. It makes them sure of the products' safety and effectiveness and that they are made according to industry standards.

- Better Work Efficiency : Using GMP standards often makes work efficiency better. Companies waste less and get better results, improving profit.

- Open to Worldwide Markets : To enter some foreign markets, a GMP certificate is often needed. This certificate lets businesses reach more markets and make more global deals.

- Less Risk : Certifications like ISO 14001 encourage sustainable practices, helping your business reduce its ecological footprint, conserve resources, and earn a reputation as an environmentally responsible organization.

Types Of ISO Certification In Uganda

- ISO certification in Uganda

- ISO 9001 Certification

- ISO 14001 Certification

- ISO 45001 Certification

- ISO 22000 Certification

- ISO 27001 Certification

- ISO 17025 Certification

- ISO 13485 Certification

- CE Mark Certification

- ISO 20000-1 Certification

- GMP Certification

- HALAL Certification

- SOC-1 Certification

- SOC-2 Certification

Get Free Consultation

Our Clients

Cost of GMP Certification in Uganda

The cost of GMP certification in Uganda depends on factors such as the size of the organization, the complexity of its manufacturing processes, and its current level of compliance with GMP standards. Typical expenses include gap analysis, training, documentation preparation, facility assessments, and audit support. PopularCert offers tailored and cost-effective solutions to help businesses in Uganda achieve GMP certification, ensuring compliance with international standards and enhancing the safety, quality, and reliability of their products.

Why Choose PopularCert For GMP Certification in Uganda?

PopularCert is a globally renowned consulting company specializing in certification, advisory, and auditing services. We are the trusted choice for organizations seeking GMP certification due to our experienced, ethical consultants and proven success record. For GMP certification in Uganda, choose PopularCert, a leader in consultancy, certification, and auditing services. Contact us, and our experts will promptly provide the best solution tailored to your needs.

GET A FREE CONSULTATION NOW

FAQ

What is GMP Certification?

GMP (Good Manufacturing Practices) Certification ensures that products are consistently manufactured and controlled to meet quality and safety standards.

How to get GMP Certification?

- Step 1: Conduct a gap analysis of your current processes against GMP standards.

- Step 2: Implement necessary improvements in hygiene, documentation, and quality control processes.

- Step 3: Submit an application to a recognized certification body.

- Step 4: Undergo a comprehensive audit to verify compliance.

What are the costs of GMP Certification?

The cost depends on factors such as the size of your organization, industry, and current compliance level. Contact PopularCert for a customized quote.

How does PopularCert assist with GMP Certification?

PopularCert offers comprehensive support, including gap analysis, documentation, training, and audit preparation, ensuring a smooth certification process.