How to Create a Quality Manual for Your Company in Al-Jafnayn, Oman — With Real Examples

Introduction

- If you’re a company working in oil & gas, construction, engineering, or services, and you’re planning to implement ISO 9001, you’ll need a proper Quality Manual.

- At PopularCert, we recently helped a client in Al-Jafnayn, Oman, build a full-fledged Quality Manual as part of their ISO 9001 implementation. In this blog, we’ll show you how we do it step by step — with real samples from the manual we prepared.

What Is a Quality Manual?

A Quality Manual is the top-level document in your Quality Management System (QMS). It describes:

- What your company does?

- What ISO 9001 clauses apply?

- How your departments and processes work?

- What policies and systems are in place to control quality?

It’s your business’s roadmap for quality, and it’s often one of the first documents an auditor will ask for.

Why Is It Important?

- Required for ISO 9001 audits

- Creates clarity across departments

- Shows clients, tenders, and regulators that you follow best practices

- Helps new employees understand how the company operates

- Supports compliance and continual improvement

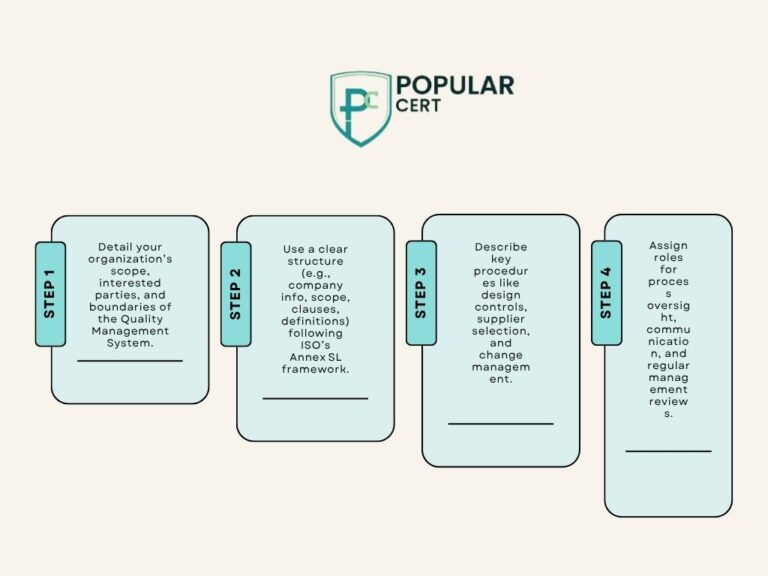

How to Create a Quality Manual — Our Step-by-Step Method

Define the Scope (Clause 4.3)

We begin by clearly stating what the manual covers, services, departments, and locations.

Example from the Manual: This Quality Manual applies to engineering, maintenance, installation, and commissioning of electrical and mechanical systems. Design and development activities are excluded as they are not performed internally (Clause 8.3).

Add the Quality Policy (Clause 5.2)

We include a one-page policy approved by top management. It should express your commitment to:

- Customer satisfaction

- Regulatory compliance

- Continual improvement

Sample Excerpt: The company shall continually improve the effectiveness of the Quality Management System and comply with customer, statutory, and regulatory requirements.

Map Organizational Roles (Clause 5.3)

We create a simple organization chart and explain key responsibilities.

Sample Reference: The Quality Manager reports directly to the General Manager and is responsible for internal audits, quality records, and ensuring adherence to QMS procedures.

Include the Process Interaction Map (Clause 4.4)

Here we create a visual flowchart showing how different processes work together, from enquiry to delivery.

Example: A PDCA (Plan-Do-Check-Act) cycle shows how customer requirements move through:

- Quotation → Purchase → Operations → Inspection → Delivery → Feedback

Documented Procedures & Control (Clause 7.5)

The manual refers to supporting SOPs like:

- Purchasing Procedure

- Human Resource Process

- Calibration & Equipment Control

- Document Control Procedure

- Internal Audit Procedure

Sample Note: Procedures are documented separately and are controlled using the Document Control Register (Doc Ref: QMS/REG/01).

Describe Monitoring & Improvement (Clauses 9 & 10)

The manual explains how the company:

- Monitors performance

- Handles non-conformities

- Reviews system effectiveness

- Implements corrective actions

Example Reference: All corrective and preventive actions (CAPA) are tracked using the QMS Corrective Action Form (QMS/F/05) and reviewed during management review meetings held quarterly.

Real Outcome

For the client in Al-Jafnayn, ISO Certification in Oman, the final Quality Manual:

- Was fully aligned with ISO 9001

- Reflected real operations, not just theory

- Was ready for internal audits and third-party review

- Helped secure tender eligibility with major clients

Types Of Certification

- ISO Certification

- ISO 9001 Certification

- ISO 14001 Certification

- ISO 45001 Certification

- ISO 22000 Certification

- ISO 27001 Certification

- ISO 17025 Certification

- ISO 13485 Certification

- ISO 20000-1 Certification

- ISO 22301 Certification

- ISO 50001 Certification

- ISO 37001 Certification

- IATF 16949 Certification

- ISO 29001 Certification

- ISO 31000 Certification

- ISO 20121 Certification

- ISO 10002 Certification

- ISO 41001 Certification

Get Free Consultation

Our Clients

What We Include in Every Quality Manual?

- Cover page and version control

- Quality policy and objectives

- Scope of QMS and exclusions

- Organization structure

- Reference to all SOPs

- PDCA cycle or flowchart of interaction

- Summary of risk-based thinking

- Record control and continual improvement mechanisms

Get Started Today:

A Quality Manual isn’t a copy-paste document, it must reflect your company’s reality.

At PopularCert, we design manuals that are:

- Audit-ready

- Easy to maintain

- Tailored to your actual operations

No fluff, just the right balance between compliance and practicality.

Need Help Preparing a Quality Manual?

We’ve done it for companies across Al-Jafnayn, Oman, Saudi Arabia, India, and beyond. Whether you’re planning to get ISO 9001 certified or need to organize your documentation, we can help.

GET A FREE CONSULTATION NOW

FAQ

What is the main purpose of a Quality Manual in ISO 9001?

A Quality Manual outlines your company’s quality management framework. It defines processes, responsibilities, and policies that ensure you meet ISO 9001 standards, making it a foundational document for audits, tenders, and internal clarity.

What should be included in an ISO 9001 Quality Manual?

A well-prepared ISO 9001 Quality Manual should include your company’s scope, policies, organizational structure, process interactions, and references to supporting procedures. At PopularCert, our manuals are audit-ready and customized to meet ISO 9001 requirements and real operational practices.

How long does it take to prepare a full Quality Manual?

Depending on the size and complexity of your operations, it usually takes 1 to 3 weeks. At PopularCert, we fast-track the process by using proven templates and working closely with your team to ensure accuracy and compliance.